- You are welcome to contact us and leave your suggestions

- Phone: 0769-26389356

- Mail:980789806@qq.com

- Fax: 0769-22708711

- Website: shaofengcn.com

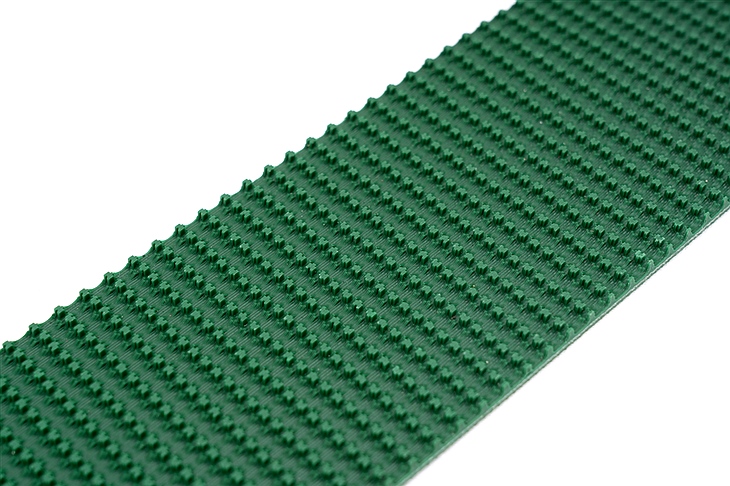

Logistics sorting conveyor belt

The rubber surface of the logistics sorting conveyor belt is made of polyvinyl chloride (pvc). The density and depth of the pattern and pattern are uniform, and the grip is strong. It has the characteristics of wear resistance, high temperature resistance and oil resistance. It is also a heat-resistant conveyor belt. The surface of the belt has a grainy pattern that is higher than the belt itself or embedded in the belt itself. The grass pattern on the surface increases the friction between the conveyor belt and the material to prevent the material from slipping. The working temperature is generally -10° to +80°. It is non-toxic, harmless and has no peculiar smell, can withstand cold and heat, has a certain ability to resist weak acids and weak bases, does not deform and is not flammable. The logistics sorting conveyor belt has a high cost performance and is a very popular product among users. At the same time, its good lateral stability makes it suitable for flexible packaging or material transportation that requires gripping or non-slip transportation.

The surface of the conveyor belt is PVC with non-combustibility, high strength, weather resistance, and excellent geometric stability.

The back of the conveyor belt is made of industrial polyester cloth, which has strong tensile force and improves the lateral stability of the conveyor belt.

Belt debugging

The deviation of the belt causes the damage of the conveyor belt, which can be corrected by methods such as rollers. After the belt is installed, there will be a certain extension. Under a certain degree of tension, the belt is allowed to rotate for 1-2 times to make the belt tension uniform throughout the entire circumference and accurately fix the tension wheel. After running for 40 hours, re-adjust the fixed tensioning wheel. At this time, the middle layer of the belt skeleton material has been fully stretched evenly and will no longer be extended.